Feb 2nd ~ The Basics of the Sewing Machine

Another fun Life Skills group took place today! Since we are beginning to grow in numbers, and still wanting to be socially distant, we made the decision to split up into small group sessions.

My group was the 'Never Before Used a Sewing Machine' group.

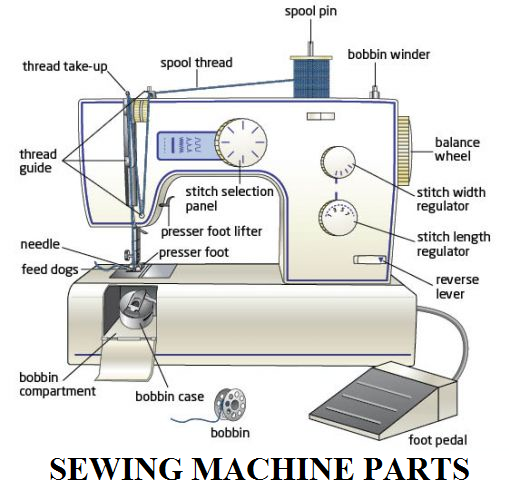

Later this season, all the girls will be doing a fun sewing project to make tie-dye, handkerchief pillows, but before we get to that point, I needed to give a course on some of the machine basics to the girls who have never used one. Because even if you have the best sewing machine you can buy from your super discount store (i.e. my model), it won't do you any good if you don't know the basics about Thread, Bobbins, and Needles, Oh My!

|

| Mint Sewing Machine - Basic Model |

For beginning sewers, it's important to start with the basics of the the machine. I had a machine for each girl, but the machines ranged from super simple, to mid-grade, to digital master! Even with the differences between them in functionality, the principles are pretty much the same.

- Balance Wheel: Lifts the needle up and down as needed, also used to catch thread from the bobbin compartment

- On/Off Switch (Not Pictured): Usually located under the Balance Wheel, most modern machines will also have a light powered by this switch

- Bobbin Winder: Used to fill an empty bobbin wheel up with your desired thread color/choice

- Spool Pin: Keeps the spool thread on the machine while in use. The spool will spin with active use and the pin helps to maintain threat tautness

- Spool Thread: Your top thread, the one that may or may not be seen depending on the project

- Thread Guide/Take Up: Components that the spool thread wraps around or through to maintain thread tautness while sewing.

- Needle: Is the workhorse of the machine, the thread runs through the needle's eye down through the center of the presser foot and out the back. The needle does the sewing

- Presser Foot: Holds tension on the material being sewn. Can rise up or down. Also is removable so other attachments can be put on such as Zipper Guides or Button Adaptors

- Presser Foot Lifter: Lifts the foot up or down

- Feed Dogs: Moveable panels that vibrate fabric forward of backward depending on sewer's desired direction

- Bobbin Compartment: Holds and rotates the bobbin

- Bobbin: Bottom thread keeper. A machine uses two threads (top and bottom) to complete a stitch. The bottom thread is usually interior on all finished projects

- Bobbin Case: Holds the bobbin within the bobbin compartment. Some newer models do not have removable cases anymore

- Stitch Selection Panel: Allows the sewer more freedom in stitch types. Med-High end machines have anywhere from 10 to 100 options! Low grade machines might combine this with the stitch width regulator to allow only the options for a straight stitch to a wider zig zag stitch

- Stitch Width/Length Regulators: One adjusts your stitches width on the project and one adjusts the stitches length on project

- Needle Position Switch (Not Pictured): A switch that can adjust your needle from center (default) to more left or more right without having to adjust your project fabric

- Reverse Lever: Allows you to sew backwards while holding the lever down

- Foot Pedal: The power to the machine, changes from lower to higher depending on the pressure you use to press it down.

Next we discussed fabric types. There are a TON of fabric choices to play with when deciding on project materials.

However not all fabrics work equally well on a sewing machine. Fabrics like cotton-blend or polyester blends are easy to use, but change over to a thick, plushy type cotton or thick, durable jean or burlap and your machine may not work with as much ease.

Thus, it's important to know what your machine is best suited to sew on (Owners Manuel), what attachments or adjustments it includes for difficult to work with fabrics, and what adjustments YOU should make when using different fabrics (slow down, use thinner threads, take your time!).

Once we got the basics out of the way, it was time to let the girls sew! They picked out fabric and worked on free hand straight stitch and zig zags, trying to keep the machine running at an even pace while maintaining a straight stitch down the fabric.

All students are different however! Some of the girls started out very slow and precise, while moving up to higher speeds and difficulties, while others couldn't seem to slow themselves down no matter how many times I guided them. But sewing is fun and this was a time for them to find what worked best for them!

However, even after the sewing begins, we have to be able to address problems that occur along the way. There are so many precision parts that must work perfectly together and if just one thing is twisted, left too loose, or a string gets caught, it often leads to a mess...

|

| Sewing and the String Bunches Up! |

There can be multiple reasons this happens, it's the sewer's job to identify the issue and get everything back in place before continuing the project.

Other problems came from either speed inconsistencies or pressure changes on the materials.

Some of the girls found that they couldn't hold the same speed with the machine the whole distance. Others noticed every time they started and stopped, those pauses could be viewed in the project sewing lines.

|

| Issues with Tightness |

Others were having issues with holding down the fabric too tightly with their hands, OR they were pushing it forward before the needle had a chance to make consistent stitches.

Nevertheless, everyone had fun and accomplished several steps in mastering their machines. I look forward to seeing them work on their pillow projects later this year!

Until next time, keep on STEMin!

Comments

Post a Comment